Wheel-rail interface study with wear analysis: measuring campaign / simulations with VI-Rail (multi-body dynamics)

TEC, a Belgian public transport operator, detected considerable wear on both tracks and wheels in some segments of their light metro network. The objective of our study was to determine the cause of this wear.

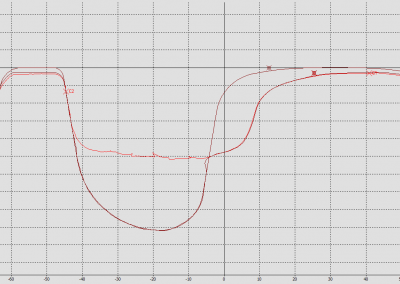

Rail profile and wheel profile measurement

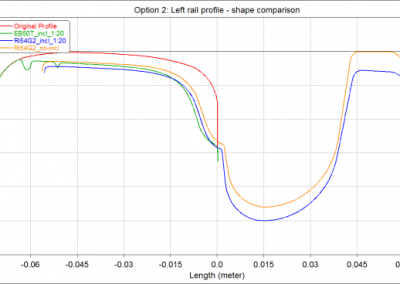

The first phase of the study involved a measurement campaign on three different sites in order to determine the real rail profile, the track gauge and the speed of the vehicle during pass-by. In addition, wheel profiles were measured with different levels of wear: new wheels, wheels with average wear and completely worn wheels. These measurements were all performed using a MiniProf.

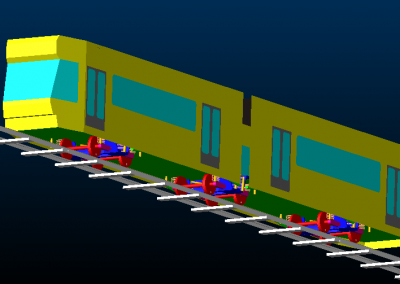

Vehicle modelling and track modelling

The second phase of the study involved a Multi Body Dynamics analysis. D2S International uses VI-Rail for wheel-rail contact analysis, for vehicle-infrastructure interaction, for modelling of flexibility of the railway infrastructure, bridges and other components, … .

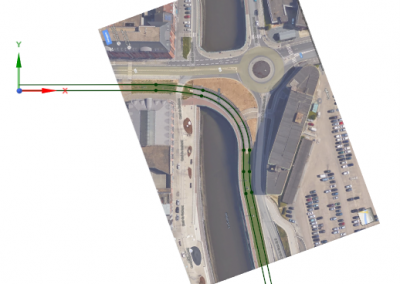

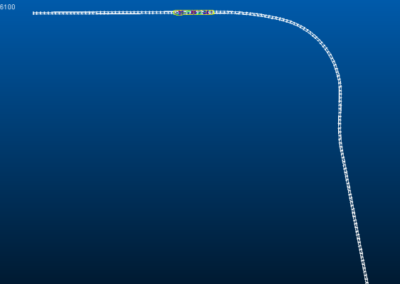

SpaceClaim was used for modelling the track. Each section, with tangent and curved segments, had to be converted into a suitable format for VI-Rail. The description of the track contains information of the center curve of the track, the variations in height of the track, the type of track, the inclination of the rails, the track gauge, … .

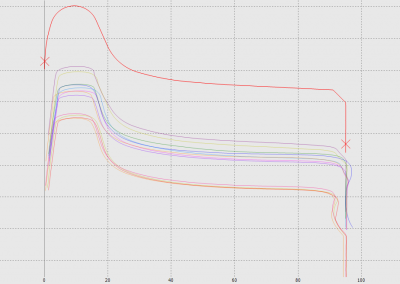

Simulations

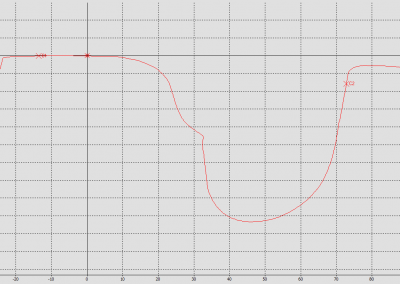

Several scenarios were studied changing different parameters (f.i. rail profile, track gauge, inclination of the rails, influence of speed, …). As a result, the location, the form and the size of rail and wheel wear were precisely determined and an appropriate solution was proposed.

D2S International is a certified reseller of VI-Grade.

For information about VI-Grade or simulation programs, check our website or contact Kris Decroos.