Anti-vibration tracks – Pre-loaded fixation systems

Pre-loaded fixation systems are discrete rail fasteners with a highly resilient under sleeper or baseplate pad.

The resilient pad is pre-compressed by specially designed springs with a load, which is about 80% of the normal static load on the fastener during vehicle passage. The pre-loading spring is completely unloaded during vehicle passage and hence no vibration transmission to the environment takes place through this rigid spring. A soft retaining spring inside the rigid pre-loading spring ensures the stability of the system. The vertical rail deflection during vehicle passage is controlled and limited by the pre-compression of the resilient pad, giving a small additional static deflection during vehicle passage.

The resilient pad consists of an elastomer that has a low dynamic to static spring rate and excellent electrical resistance and thermal stability. The dynamic stiffness of the system can be as low as 5 kN/mm (at 20 Hz), ensuring a first wheel-rail vertical resonance below 20 Hz and hence excellent vibration isolation characteristics, comparable to those of the floating slab.

The system is designed in such a way that it can be fitted directly:

- onto a concrete slab or a steel frame;

- onto concrete or wooden ties;

- in ballasted tracks as well as on ballastless structures;

- at grade, below grade and on elevated structures.

It can be used for all types of lines: train, commuter rail, metro, tramway, turnouts, …

It is also adapted to embedded tracks.

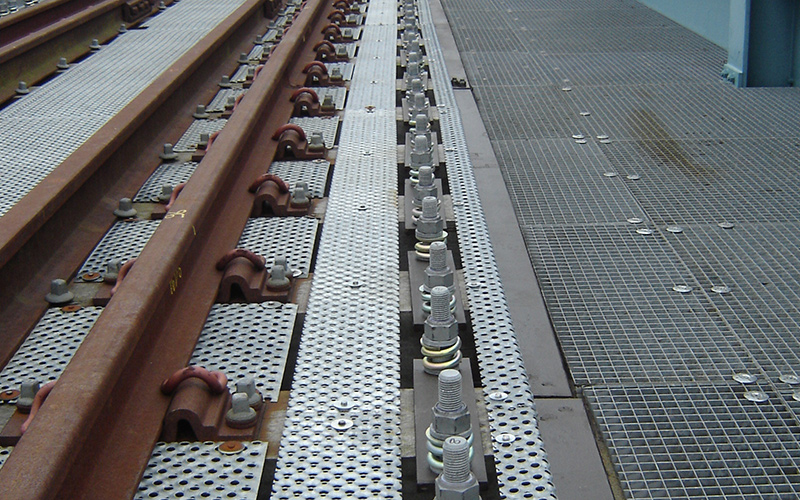

New York metro, steel viaduct

Since the fastener had to be delivered as a single unit, it had to be assembled on a steel plate that in turn is bolted to the wooden sleepers.

The thickness of the steel plate was determined as ½” (12 mm) to provide a secure anchor for the 1″ (25 mm) diameter studs that form the backbone of the pre-load system. This meant that there was only room for ¾” (19 mm) of vibration damping material. The solution consists of a 3 mm thick rubber sheet studded with natural rubber discs with a diameter of 35 mm and a height of 19 mm.

Comparison of ground borne vibration levels between standard NYCTA track and track with the D2S International fastener at Grand Street Station.

Paris metro, North bridge

Several Lines of the Paris Metro RATP operate over steel bridges dating from the early 1900’s. A rehabilitation project was the perfect time to redesign the trackwork of the Pont Du Nord and offer a significant reduction in vibrations and emitted structural noise. The Pont Du Nord is situated on Metro Line 2 close to La Chapelle station.

The steel structure is almost 100 years old. The rails are mounted on wooden ties which are bolted directly to the steel bridge. The special designed new trackwork consisted of an elastic prestressed layer under the sleeper reducing the noise by 6 dB(A).

Milan metro, Famagosta – Abbiategrasso extension

In Milan, the systems were directly installed on the concrete slab. In the considered curve, the maximum axle load was estimated to be 40 kN.

The base plate pad was developed to have a thickness of 50 mm and a vertical static stiffness of 5 kN/mm.

Two compression springs with a spring rate of 6 kN/mm are compressed 2 mm to produce a pre-load of 24 kN, resulting in a resilient fastener with limited displacements.

Antwerp tram, embedded track

On this site, a tram had to make a curve with a radius of 25 m. Tracks systems had to be embedded in the street pavement and constructed on a concrete slab. Noise studies before construction indicated that noise and vibration levels would be very disturbing for the houses very close to the track.

The highly damped rail fixation system with a resiliency high enough to provide lateral rail deflection and damping was installed to minimise the lateral stick slip of the wheel on the rail that initiates the squeal. The installation was executed following a top down process. Once the track is in place, specially developed rubber caps are placed over the fastener, one on each side of the rail. The caps are designed to protect the fastener from infiltration by concrete that can prevent the working of the spring or even block the movement of the base plate pad.

The performance of this track has been measured after installation and during passage of the Siemens tram (equipped with resilient wheels). Most tram passages did not generate squeal noise at all. For some rare single passages, the measured maximum squeal noise at a vehicle speed of 10-15 km/h at 7.5 m from the track was 80.5 dB(A).

In comparison, the calculated squeal noise level for a classical track at 7.5 m from that track was 102.7 dB(A). The very resilient rail system thus reduces the squeal noise, if any, by more than 20 dB(A). This result is very satisfying and leads to more installations of this type to prevent squeal noise in tight tram curves.

Ostend, freight operations in urban maritime environment

The steel bridge is used for rail traffic destined for the port of Ostend. The aim was to develop a general-purpose track based solution for noise reduction of steel bridges (radiated noise). The bridge was constructed in the year 2004 and 2005. A modal analysis measurement of the bridge was performed and a customised fastener was designed.