Noise and Vibration

Structural vibration can be a source for many product related problems; it can cause fatigue and durability problems to the product itself, and it can cause adverse reactions to the user or bystanders in the form of undesirable vibrations that can be felt or heard. As well, undesired structural vibrations can prevent products from operating as required and potentially becoming a safety concern. Often referred to as NVH (Noise, Vibration, and Harshness) or N&V (Noise and Vibration), this problem is one of the most often directly perceived quality traits of a product, and is therefore one of the most sought after targets for performance by the product development team to help differentiate themselves from competition.

Hexagon (MSC Software) offers leading CAE solutions to help customers understand and address product NVH issues with virtual prototypes, helping to reduce product developments costs, accelerate time to market, and optimize noise and vibration performance. With leading FE (finite element) and MBD (multi body dynamics) capabilities from Hexagon (MSC Software), users can simulate and predict how a component or system will vibrate under varying operating conditions; for example how a driver or passenger of a car driving down the road can perceive the engine sound at cruising speed or under acceleration and at the same time perceive the feel and the noise generated as the car runs over a pot hole. Engineers in almost every industry use Hexagon’s (MSC Software) applications to improve performance, reduce weight and reduce costs. Based on over 40 years of experience in solving industrial problems, Hexagon (MSC Software) has developed some of the most efficient and accurate solver techniques and methods that have been implemented to help solve the largest and most complex systems NVH problems encountered.

Structural Vibrations

Understanding the structural vibration characteristics of a component or system typically requires the engineer to understand both the natural vibration characteristics of the structure, also known as vibration modes, and how the structure responds to external loading factors, typically referred to frequency response and transient loading. Hexagon’s (MSC Software) NVH solutions provide capabilities for linear and non-linear modal, transient and frequency response analyses for structural components, systems and mechanical assemblies. When noise or durability are a concern, this vibration information can then be used to perform coupled acoustics predictions for interior or exterior noise, or it can be used to perform product fatigue predictions, using the detailed, vibratory and transient loading histories obtained in the vibration simulation.

FRF Based NVH Analysis

Another challenge in NVH analysis is identifying the path of energy flow from source to a point of interest, and it is also beneficial to understand the source of undesired vibration or noise well in advance of vehicle assembly. Hexagon (MSC Software) provides a Frequency Response Function (FRF) based methodology to help address this need.

FRF represents the frequency response of components due to unit loads at a given frequency. The FRFs of components can then be combined to yield the FRFs of assemblies of these components. An advantage of this approach is that it lends itself to transfer path analysis (TPA). Through TPA, users can trace the energy flow from source to receiver. This allows identification of critical paths and noise sources. For instance, in the top left picture, the source of noise is the engine and in the bottom picture, the noise source is due to tire loads. Thus, to understand and improve vehicle NVH, it is necessary that the engineer perform a full system analysis, and MD Nastran enables this by proving the desired scalability with its application specific solvers.

Internal and External Acoustics

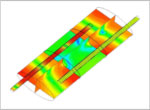

Hexagon (MSC Software) offers proven solutions and techniques for simulating and predicting what are typically called internal and external acoustics. For internal acoustics, Hexagon (MSC Software) provides a coupled Fluid-Structure Interaction simulation which calculates the pressure inside a bounded domain. This is used to solve for sound pressure levels experienced by the occupants. For exterior acoustics, the solution provides a structural vibration coupling with exterior acoustics simulation techniques. This capability is used to analyze the sound field radiated by a vibrating structure in a single coupled vibro-acoustic analysis. With the use of infinite elements, the need for large meshes of the field around acoustic sources is eliminated. In addition to the sound pressure level calculations, Hexagon (MSC Software) provides analysis techniques that allow the engineer to identify which components in an assembly are contributing the most to a particular noise, something referred to as panel participation.

Large Model and Assembly Simulation

Critical NVH characteristics, those observed and perceived by the user or bystander, are complete vehicle system problems. That means that in order to simulate these behaviors, the simulation model must represent a nearly complete vehicle system. This can lead to very large computer models of the structural and mechanical system assemblies. Hexagon (MSC Software) offers industry proven, high performance methodologies for correctly and efficiently modeling and simulating these types of models. This includes techniques for correctly modeling welded, glued, and fastened assemblies, as well as jointed connections; ACMS – Automated Component Mode Synthesis for faster, parallelized modal analysis of large models; and External Superelements for use in assembly process – Superelements enable logical partitioning of a full-vehicle and reuse of component information helping reduce solution time. Based on over 40 years of experience in solving industrial problems, Hexagon (MSC Software) has developed some of the most efficient and accurate solver techniques and methods that have been implemented to help solve some of the largest and most complex systems NVH problems seen.

Request information

D2S International offers consultancy services using finite element software from HEXAGON (MSC Software).